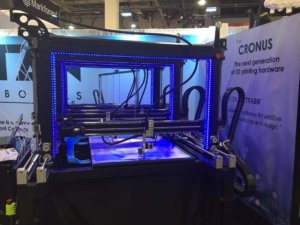

At CES 2017, large format 3D printer manufacturers Titan Robotics, from Colorado Springs, announced that the 5-print-head Cronus 3D printer will be available to buy from February 2017. As the time approaches, 3D Printing Industry take a closer look at the Autodesk Project Escher technology that makes it tick.

At CES 2017, large format 3D printer manufacturers Titan Robotics, from Colorado Springs, announced that the 5-print-head Cronus 3D printer will be available to buy from February 2017. As the time approaches, 3D Printing Industry take a closer look at the Autodesk Project Escher technology that makes it tick.

FFF 3D printing through a single nozzle takes time, especially when creating an object bigger than your average mini Eiffel Tower or 3D Benchy. For 3D printing to compete with traditional modes of manufacturing, this process needs speed. And Autodesk’s Project Escher is one answer to that.

Project Escher is a computer system that programs multiple heads to print the same object. It currently works as a plugin for Autodesk’s additive manufacturing design software Netfabb. The idea of Escher comes out of Autodesk’s Pier 9 workshop in San Francisco that unites makers, artists and engineers in a similar way to Fab Labs.

As Andreas Bastian, Principal Research Scientist at Autodesk, explains in a video demo of the Cronus, the problem isn’t how fast you can get print head to move, but how fast you can melt the plastic. An additional challenge arises in getting multiple heads to perform different tasks towards the same end goal. It’s sort of like learning to play a musical instrument, with your right and hand and left hand controlling different parts. But the Titan Robotics Cronus 3D printer has five arms instead.

The Cronus manages to 3D print a build size of 77 x 30 x 20 inches (L x W x H) by implementing Project Escher into the paths the print heads take to make a print. The paths are processed through a Raspberry Pi chip that works as a brain or ‘conductor’ for the Cronus. As the heads move independently of one another, it means that Cronus is capable of printing one complete object, rather than multiple copies of just one part of it.

Prepared on the basis of information from 3D printing Industry