John Mark Ltd is a company that already has an enviable reputation as a leader in the field of digital wallpaper. Owner and director, John Mark Watson himself is a fourth generation wallpaper manufacturer, so you could say that wallpaper is quite literally in his blood. I visited their operation in Leyland, Lancashire, UK to discover more and talked with John Mark, and Jason Gilliat, Business Development Manager.

John Mark Ltd is a company that already has an enviable reputation as a leader in the field of digital wallpaper. Owner and director, John Mark Watson himself is a fourth generation wallpaper manufacturer, so you could say that wallpaper is quite literally in his blood. I visited their operation in Leyland, Lancashire, UK to discover more and talked with John Mark, and Jason Gilliat, Business Development Manager.

Tell us about the background of John Mark Ltd

I set up the business in 2012. I had worked up to that point in the family business but had to leave and needed to work out what to do next. I went out to dinner with an industry contact (who is now one of our biggest customers) - he said he was interested in digitally printed wallpapers.

My uncle in his business (not wallpaper) was looking into digital print and I could see the possibilities were interesting.He was involved in the world of making credit cards and gift cards. They were looking at digital for personalised gift cards as the technology was getting better and better.

I then met with an old paper supplier and discovered that Hewlett Packard were bringing out a new water based latex machine. I thought deeply as to whether I should take my experience in wallpaper into the digital print world but at the time I just didn’t have the money.

Digital print was flat. The challenge for me with was to maintain the authentic textures and movement associated with a surface printed wallpaper.

We worked with one designer in particular - Adam Caulkin. He had brush strokes within his designs that reproduced beautifully as a screen print. We printed it digitally from the same files but our digitally printed version just didn’t look right. We really had to play with it to make it look like the screen print – we were successful! Our customers began to like what they were seeing and this gave me the confidence to invest in the HP LX600 in July 2012 with the backing of my uncle’s family business.

What were the main challenges for you, as you were used to surface printed wallpaper?

What was really challenging initially was the software. This was a problem. We had to involve HP to work with AVA in order to achieve uniformity across presses and substrates.

It was Jane Rixon at HP who really pulled us all together. Once the RIP companies understood what was needed it really opened up the wall coverings industry from a digital perspective for us. We worked closely with our suppliers, and still do, to develop the hardware and the software to create commercially viable, digitally printed wall coverings. I am a pretty hands on guy so this suits me, I enjoy it. We learned a lot in the early days and now we are reaping the rewards.

By May 2013 we were getting busier and busier so we invested in the LX 820 to meet demand.By this time the big names in wallpaper design and production were beginning to get curious and wanted to investigate the possibilities of digital for their own brands. The companies who got involved early on included Osborne and Little, Romo, Designers Guild & Lewis and Wood. All these people came to us because they were intrigued - we trialled their patterns on a variety of non-woven substrates and low and behold they placed orders!

It just went boom!!! And we haven’t looked back. I got involved with digital early on and the machines we invested in back then were pretty soon running non-stop. Now we invest in new machines as we approach capacity. It was tough to begin with but I have no regrets – it was the right path to take.

What do you put this success down to?

It was fate I think. Although it was difficult leaving my family business, I was lucky to have some nice customers to support me. I think I have always worked well on pressure induced adrenaline. If I have orders to get out, I get them out. I still come in at weekends and evenings - I am passionate about wallpaper and the wallpaper industry is my family. Someone once said that if I cut myself I would bleed wallpaper paste!

We are really inspired by bringing to life design ideas. I can talk to the customer and listen, and I know I have a specialist ability to interpret a design, to get that design on a paper, take the image and enhance it. I help the designer, and they look to me to make the design really special. This attention to detail, this care, I think is what sets us apart.

We treat each and every design individually. It really is not as a mass production type of thing. It is my interpretation of the design onto a roll of wallpaper that the designer wants. The rest works itself out.

How is the wallpaper production market different to traditional print markets? I asked Jason this as his background is in graphic design and print.

This is a special market to work in. It is the higher end of the wallpaper market - an aspirational product, not a functional or commoditised one. So it is not generally price led.

I deal directly with designers, I think being a designer myself really helps – we speak the same language, understand the same design software and have the same end goal – to hear wow! There is a not so famous graphic design quote: “There are three responses to a piece of design – yes, no, and WOW! Wow is the one to aim for.”

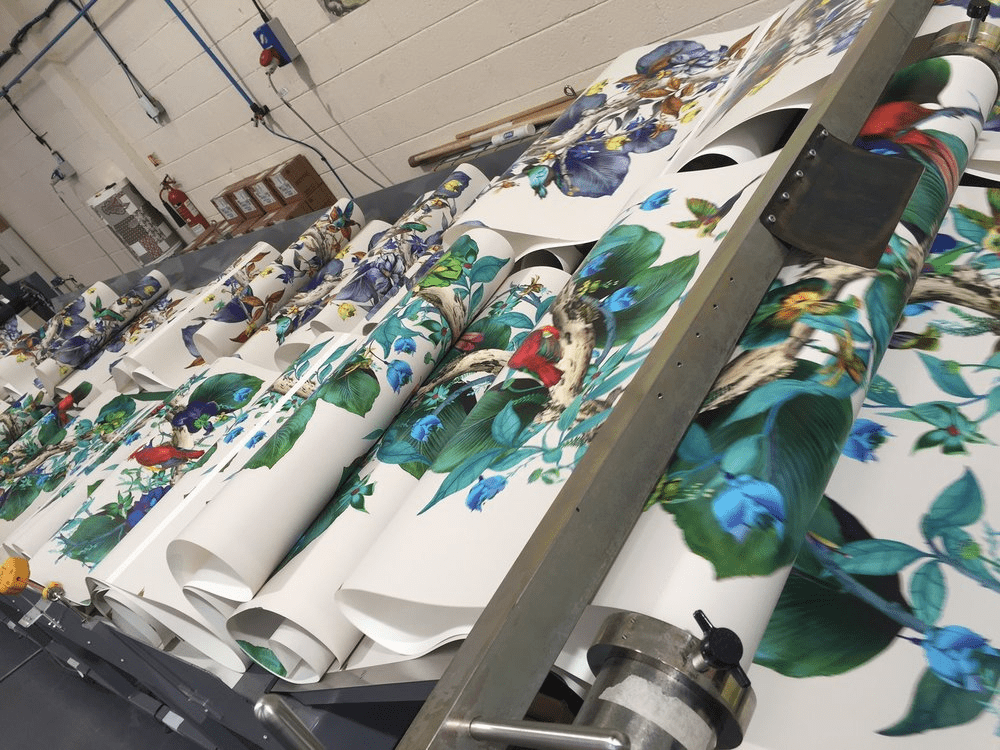

The wallpapers we produce are so diverse - from faithfully recreated surface pattern designs at traditional widths (52cms) to superwide (145cms) three panel repeating rolls that are literally works of art in wallpaper.

More and more designers are breaking free from the constraints of traditionally printed pattern that is limited by the circumference of the roller. Equally liberating is not having the financial constraints of taking a product to market – no huge set up costs and no need to carry large volumes of stock.

What we think we have done here, particularly with John Mark’s experience and dedication, is to define the possibilities of digital print in the wallpaper industry.

Why is digital wallpaper proving so popular?

It is not mass produced. And this is the value.

These products are out-performing analogue because they are more appealing. Our digital process is also a much more environmentally friendly affair than traditional methods. Our ink system is water based, our non-woven substrates and made from recycled materials, and there is very little waste compared to the old way of printing wallpaper.

Digital is popular with designers. A designer may have a collection of 30 plus patterns / colourways and digital makes this possible to produce them all.

As we have added more machines and increased our capacity we have been able to drop our minimum order from 25 to 10 rolls. And within these 10 rolls, they can produce 10 individual designs!

So why aren’t other printers ALL doing what you are doing and digitally printing wallpaper?

The real misconception is that digitally printed wallpaper is easy to work with. Personally, I don’t think that a traditional graphic print company would find it easy to jump into this market. The dynamics and technical demands are different. You can’t just press and print. You do need wallpaper experience as it is technically and aesthetically challenging.

It’s not a case of putting ink onto paper and hoping for the best!You need to be in the world of wallpaper and to know your clients. I had this advantage, I knew who to speak to, and this helped of course.

We have an in-depth understanding of digital. People cannot work out exactly what it is we do what we do and the success we have had - of course this is something we want to continue to enjoy.

Back in 2014, some analogue wallpaper print companies also invested in digital. Of course this created a little competition but most of them seemed to get it wrong. The colour wasn’t consistent and the print mark was poor which is unacceptable with wallpaper printing.I think you have to be focused - this is why it works for us - we are 100% focused on digital.

So what about the future?

Fortunately, our current premises have enough room to put in extra machinery to satisfy the increasing demand. We just installed 2 new presses and we are looking at a new development that will bridge the gap for digital in larger roll orders that would otherwise have to be printed gravure. We are also exploring added value finishing techniques this year – watch this space!

Texture is really growing in importance for the digital product. We are always on the lookout for new substrates. We currently offer an extensive range of non-wovens (coated and un-coated), vinyl, foil, grass cloth and non-woven backed textiles.

We will continue to do what we do best, and build our business around the needs of designers. This has served us pretty well so far.

Prepared on the basis of information from Industrial Print Blog.